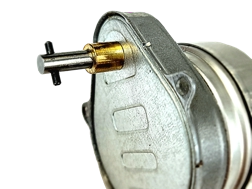

1. After removing old motor, mount new shaft on damper as

illustrated in Image 2. Cross pins on shaft will fit into

damper. Retainer strap (bendable strap with holes) will be

screwed onto damper to hold damper shaft in place. The

retainer strap will bend over the washers on the damper

shaft and not sit flat on the damper. Take care to place

brackets where shown to avoid self-tapping screws from

interfering with internal damper mechanisms.

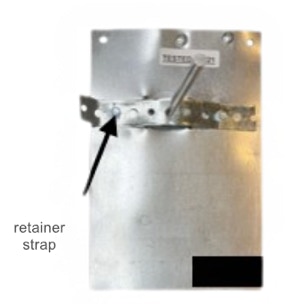

Note: If you are removing the motor from a rectangular damper with a 3150 RetroZone™ motor, you will need to remove the motor box or "fold" down the sides of the motor box so they are flat against the damper to be able to install the Belimo motor.

See Image 3.

2. If damper can be removed, then remove the spring from

inside of the damper since it is no longer needed, although it can be left in place.

3. Make sure new shaft can be rotated easily. Note with

marker where the fully open and fully closed positions will

be. Please also note that the retainer strap should apply

little or no pressure on the new damper shaft; its purpose is

simply to keep shaft secured to damper.

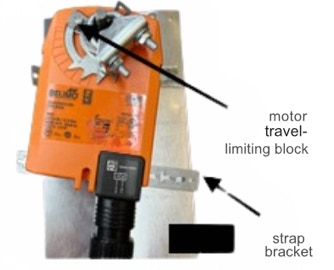

4. TFLB motor is already in closed position. Mount on new

damper shaft after also fully closing damper. Note where

anti-rotation bracket should be placed; mark position; and

mount anti-rotation bracket with strap bracket. See Image 3.

Can't tell if your damper is open or closed - please go to

www.RetroZone.com and click on Technical Resources.

Direction of travel of this motor is controlled by putting either

orange or gray side away from damper face to reverse

directions. As needed, stroke limiter can be moved from one

side to the other. If you need the motor in the open position,

consult "Remounting the Stroke Limiter on the Belimo TF Series Motor", included with this kit.

5. VERY IMPORTANT: Rotate damper to fully open position

USING POWER ONLY - DO NOT attempt manual rotation.

Then, with Phillips head screwdriver, move motor travel

adjustment blocks to stop the motor from further travel. See

Image 4.

NOTE: DAMAGE can occur to the damper if the powerful

Belimo motor is allowed to exert full force beyond the travel range of the damper.

Electrical Hook-up of Belimo TFLB Motor to Zone Control

System: Refer to zone control specific information on your

system for electrical hook-ups, However, when using the

TFLB24 Belimo Motor simply reconnect the two wires used on

old motor. Since these are AC motors, there is no polarity either

of the motor wires may be used in either position.